Refractory Application and

Monitoring Beyond 1200° C

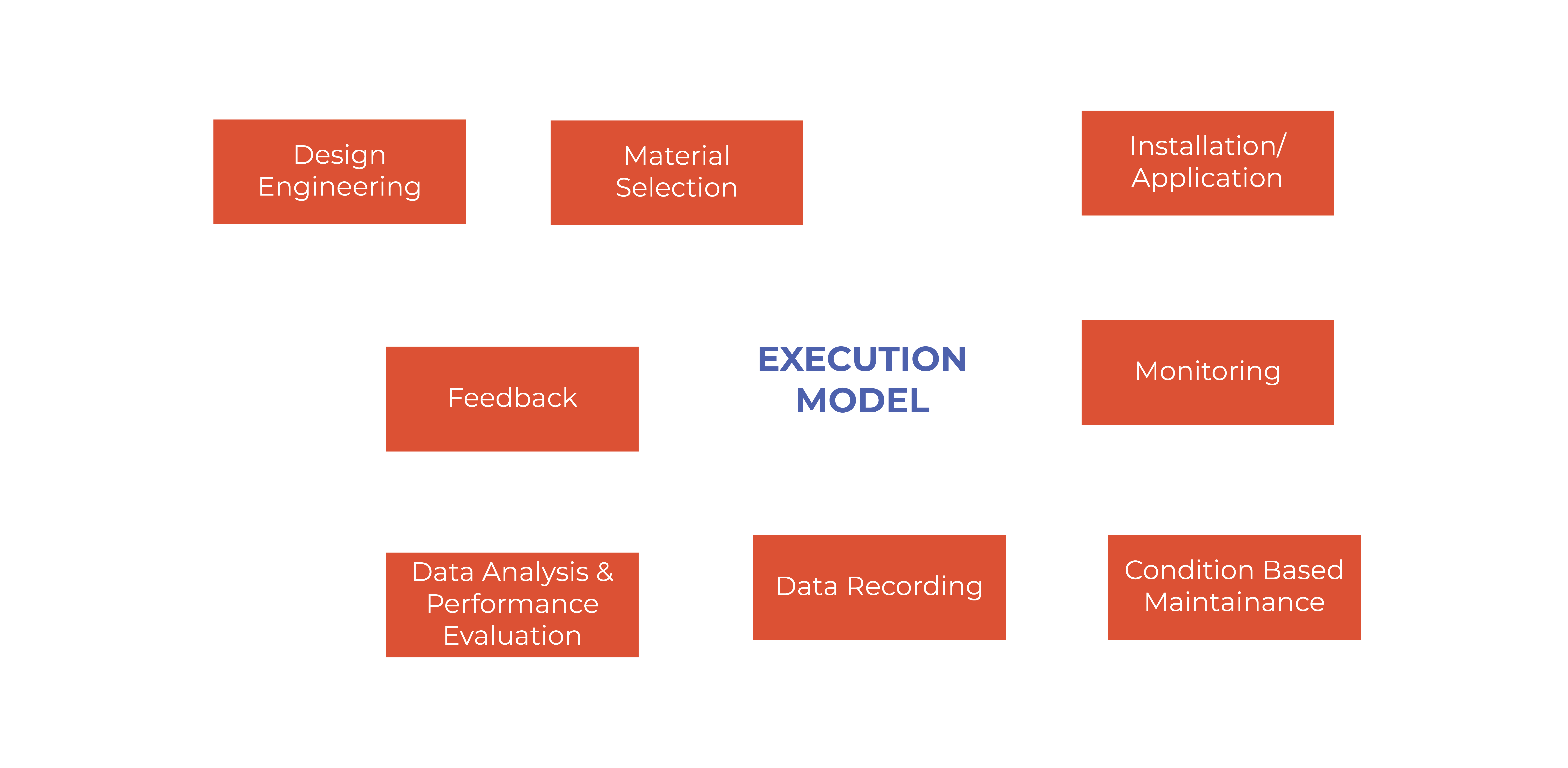

SARVESH understands the challenges of operating in extremely high-temperature industrial processes. With temperatures reaching 1200°C and beyond, specialized equipment is a necessity. That's why we're proud to offer our customers tailored solutions and services through our Refractory Application Machinery. Our complete portfolio of special machinery and services is designed to meet the demands of

- Torpedo Ladle Management

- Ladle Operational Refractory Management

- Total Ladle Management

- BOF and EAF Management

Maximizing Performance,

Minimising Downtimes

LEADING THE CHARGE -PROJECTS UNDERTAKEN

Slide Gate Management at RSP VSP, DSP & BSP

Steel Ladle Management at RSP, BSL, DSP, ISP & RINL

Purging Management at RSP, BSP, DSP

Tundish Management at RSP & BSL

Rotary Kiln Management at BSL

Hot Metal Ladle Management at BSL

Torpedo Ladle Management at RSP, BSL

Converter Management at RSP & BSL

A Glimpse into Our Success

Browse Our Application Sites for our Most Successful Projects

-SAIL-Bhilai Steel Plant: Total Ladle Management at SMS-II & SMS-III

-SAIL-Rourkela Steel Plant: Total Tundish Management at SMS,

LORM at SMS-I & II, Steel Ladle Refractory on Supply & Application basis at SMS-I & II, Converter Management at RSP SMS-II

-SAIL-Bokaro Steel Plant: BOF Management, Total Tundish Management, Rotary Kiln Management, Steel Ladle Refractory on Supply & Ap- plication basis, Hot Metal Ladle

-SAIL-IISCO Steel Plant: Steel Ladle Refractory set on Supply & Application basis

-SAIL-Durgapur Steel Plant: Steel Ladle Refractory set on Supply & Ap- plication basis, Slide Gate and Purging Refractories